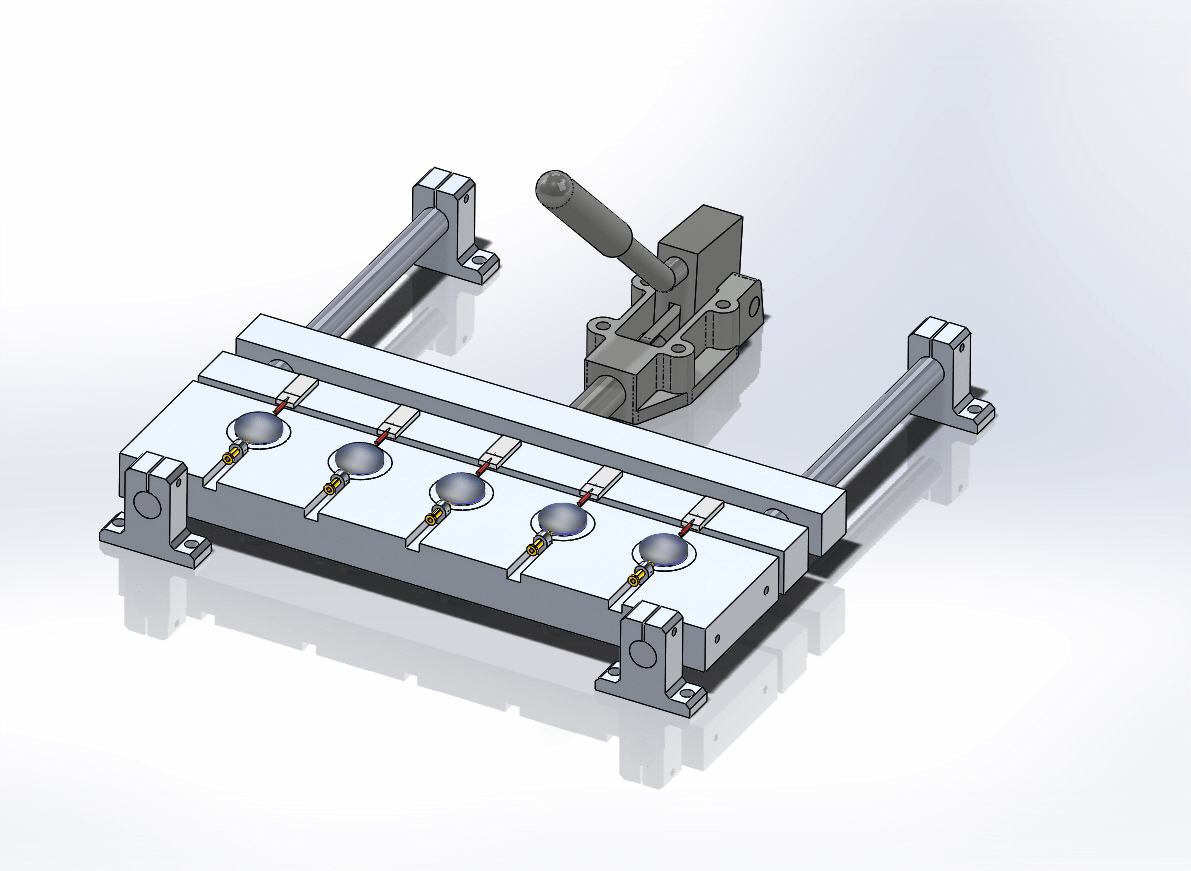

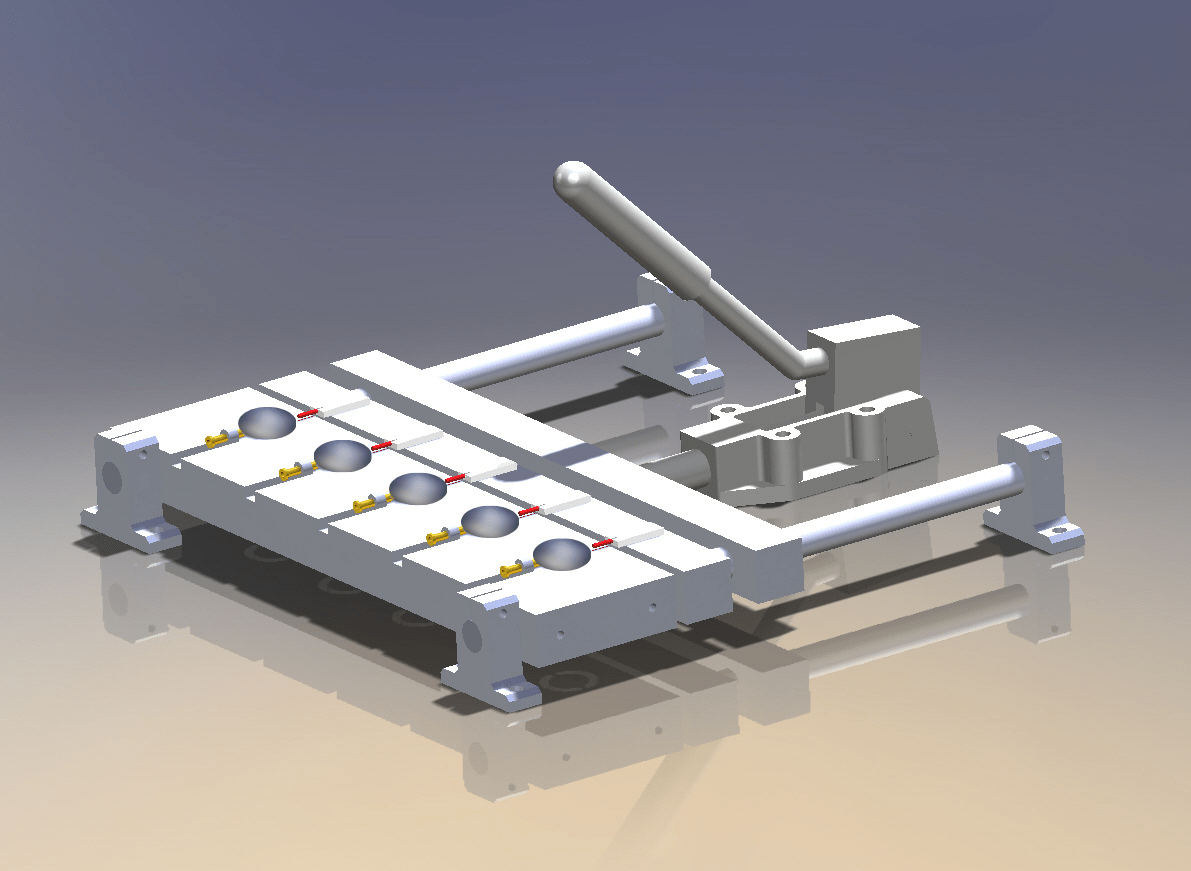

IPP’s assembly tool – A clever solution

For one of our projects, IPP has created a “one-package service” to fully assist and unburden the customer. From components to assembly, to full control over this process, IPP covers 100% quality-conforming wishes. This includes end-of-line packaging to support and cover the complete assembled product, created for one of our major customers.

About the tool:

With this tool, we are able to assemble specific parts, both by hand and within automatic mode. An important step in this process is the check-up from the camera system for controlling alignment, position, and quality of the product. Also, data storage of each assembly will be in place. This is all to avoid mistakes and to have control over this process.

Here are some additional benefits of a tool that assembles, checks, and fixes a custom-specific design:

Overall, this type of tool can have a significant positive impact on the productivity and quality of assembly work. The tool could guide the worker through the assembly process, ensuring that all components are correctly in place.

As you can see, we do not only assists in the design of a specific component or end product but also in such specific solutions to unburden customers within their needs! With IPP and all of their principals, we fully assist from the first idea to prototype to primary design up to final design and production. If you seek a solution within your electromechanical or opto-electrical needs, we are the right address to approach.

This is just an example of the service we offer all of our customers. Just ASK IPP!