New England Keyboard

Full Travel Keyboards | Silicone Rubber Keypads | Key Panels, Assemblies & Terminals | Ruggedized Military | Membranes & Membrane Switches | Kapton Cables & FFC Assemblies | LCD’s & LCM’s | Cast Metal Components | Touch Panel Displays | Molded Plastic Parts

New England Keyboard, Inc. (NEK) is an engineering and design company specializing in the design and manufacture of custom keyboards, keypads, and membrane switch keyboards, including custom electronics and enclosures. In addition to our data entry products, we offer a large variety of custom components including: resistive and capacitive type touch screens, Kapton® cables, bare rigid-flex and flex PCB assemblies, military grade LCDs, cast metal components, and in-mold decorated (IMD) components, to name but a few.

New England Keyboard’s full travel keyboards are rugged, reliable, and designed to meet the most demanding applications and environments. Available with either a linear feel or tactile feedback (mechanical “click”), NEK’s sealed keyboards will stand up to liquid and solvent spills, dust, contamination, and extreme temperature. Our waterproof full travel products feature a unique water tight “sleeve” under the keycaps to seal the bearing surfaces from water. Combine with a water resistant trackball or sealed rubber pointing device to create a complete waterproof high speed data input device. Inexpensive EMI/RFI shielding can be easily incorporated.

Product features

New England Keyboard’s rugged, short stroke, custom silicone rubber keypads offer substantial design flexibility. Choose keypads only, complete assemblies, sub-assemblies with display, LED indicators, bezels, custom electronics, and many other features. Customer specified key dimensions (size, height, and shape), color, legend, and layout. The design flexibility of our Silicone Rubber Keypads is almost limitless.

Product features

New England Keyboard, Inc. designs and manufactures terminals, stand-alone products, and higher level subassemblies utilizing all of the following technologies: membrane, Kapton®-membrane, elastomer rubber, full travel switches, discrete switches, and touch panels. These more complex products are typically panel-mounted or in enclosures. Low profile sealed laptop style keyboards are available with or without backlight or a sealed, embedded pointing devices such as a mouse touch pad. Into all of these products NEK can incorporate an almost unlimited combination of the following features:

Product features

New England Keyboard’s custom flat panel membrane switches, with special solvent resistant textured overlays, will stand up to the harshest environments. They are suitable for most applications and can be manufactured to your exact specifications. They can be supplied as complete turnkey assemblies that incorporate custom electronics and LED indicators and can be packaged in standard or custom enclosures. NEK’s membrane panels are currently used in diverse applications such as Military and Industrial Equipment, In-the-Vehicle applications and commercial kitchens. Membrane keypads manufactured from etched Kapton® feature solid copper traces for high current carrying capacity, 0.5mm connector pitch, and extremely high temperatures. Surface mounted components and connectors can be solder attached using conventional reflow techniques.

Product Features

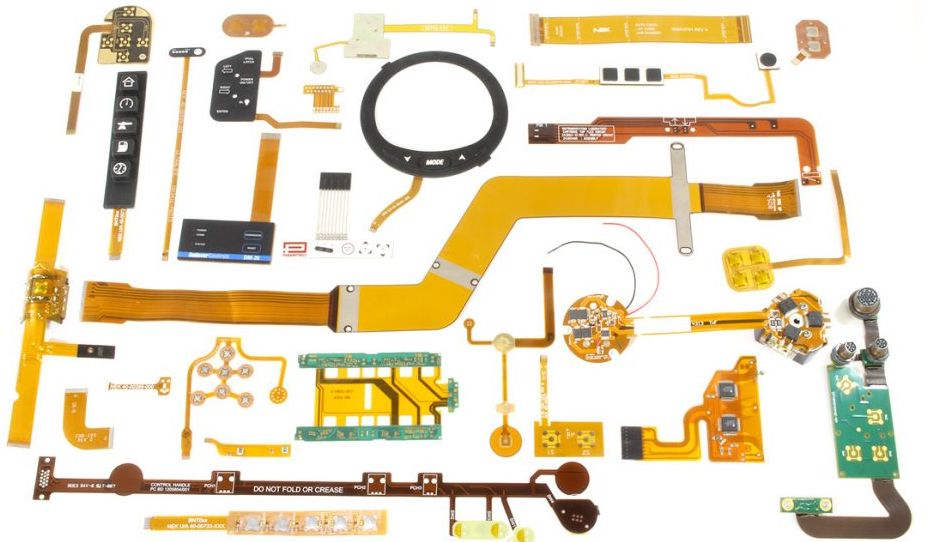

Kapton® cables, assemblies, and FFCs from New England Keyboard, Inc. help you to reduce assembly costs, reduce weight, meet dynamic flexing requirements, and eliminate connectors, thereby increasing reliability and repeatability. NEK’s on-shore design and engineering support coupled with our off-shore manufacturing provides you the ideal combination of service and price.

Kapton® & Assemblies

Flat Flex Cable & Assemblies (FFC)

New England Keyboard, Inc. is an ITAR registered corporation with ITAR licensed factories in Taiwan. We manufacture a large variety of products used by the Military or in very harsh environments. We build products with foil shielding and conductive lenses that meet Mil 461E & Mil 462 specifications for radiated electromagnetic emissions. NEK manufactures key panels with liquid crystal displays (LCDs) which pass the Ship Board 500 pound Hammer Weight Shock Test. NEK can use a combination of our in-house test lab and local test houses to perform qualification testing to verify products are compliant to a large number of Mil specifications. From straight forward subassemblies to complex turnkey devices, NEK’s engineering staff can design, build, program, and perform qualification testing to deliver you a ship-to-stock solution.

Products NEK produces

New England Keyboard, Inc. manufactures rugged Liquid Crystal Displays (LCD’s) and Liquid Crystal Modules (LCM’s) for a variety of demanding applications. Our products are “on the battlefield” in tens of thousands of military radios all around the globe. We build displays with wide temperature range fluids and shock absorbing inner layers. Products incorporate integral heaters for operation to -45C. NEK offers many products with NVIS (Night Vision Compatible) backlighting. LCD’s can be incorporated onto customers’ controller card for cost savings.

Product Features

New England Keyboard, Inc. offers a variety of casting methods and materials to guarantee you the most cost effective approach based on individual applications. Part size, complexity, surface finish, and production lot size determine the method to be used. Complete, state-of-the-art machining capabilities provide tight tolerance dimensional features, through holes, threaded holes, under cuts, etc. Painting, plating, powder coating, and printing operations finish off the product offering.

Product Features

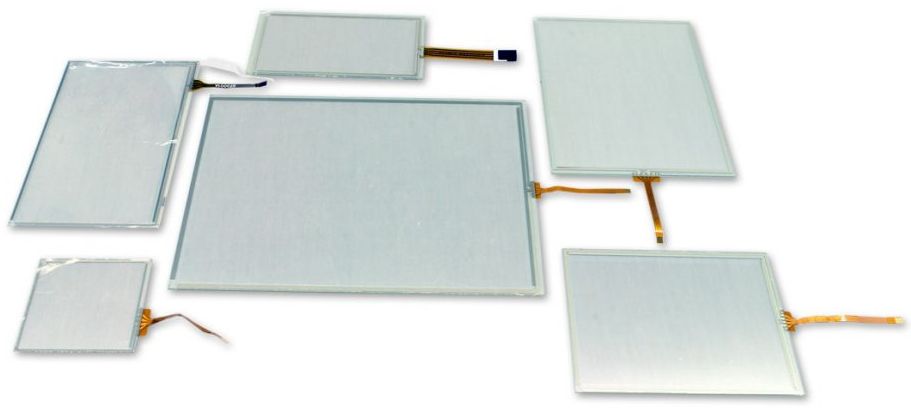

New England Keyboard, Inc. standard touch panels are smart modules with integrated LCM displays and touch screens. To create the display graphics, a large library of graphic objects are available, or create your own objects on your computer in a number of popular file formats and download to the module. Setting the touch sensor coordinates is straight forward and intuitive. Animated graphic objects are easily created. Complete custom LCD designs are available to fit your exact requirements.

Product Features

New England Keyboard, Inc. has degreed Plastic Engineers on staff to design your component to take advantage of plastic material’s inherent strengths and accommodate their weaknesses. We take your project from concept, through part design, mold design, mold manufacture, and finally part molding. Our off-shore ITAR licensed factory has an on-site paint shop. We can apply conductive spray coatings, decorative painting, rubberized paint, and printing. We mold military components in UTLEM, Peek and Zytel, up to 30% glass filled. Vacuum metalizing, metal sputtering, and metal plating including 2 shot molded parts with metal plating and clear lenses are available.